we continue to be the address of quality,

innovation, and trust in glass production!

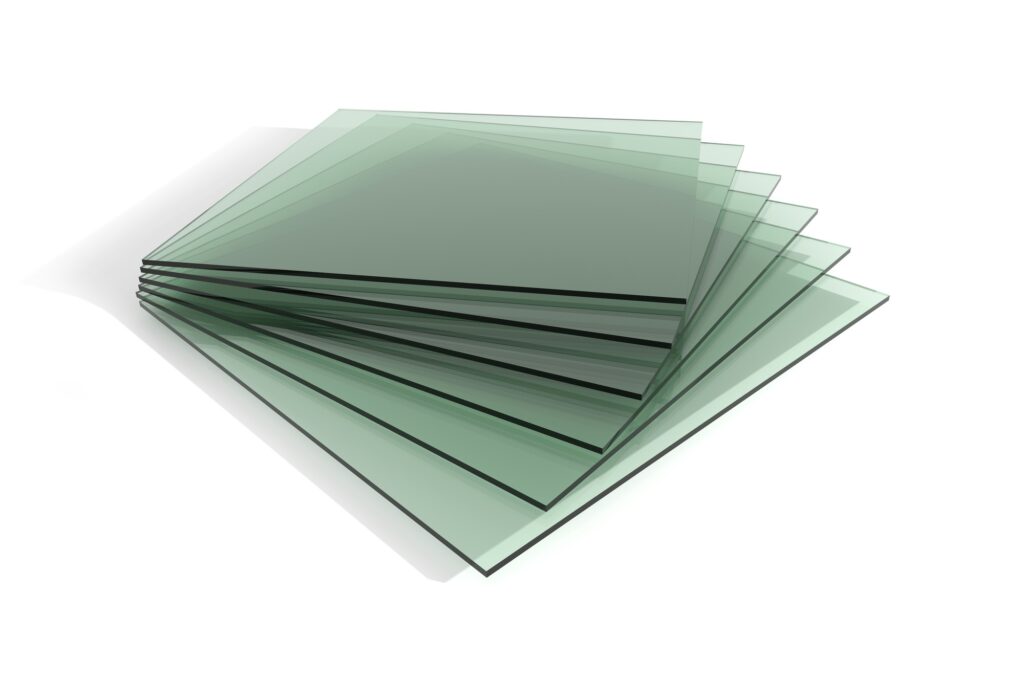

Tempered Glass

Tempered Glass

What is Tempered Glass?

Tempered glass is a type of glass that is strengthened by a special heating and cooling process, which increases its durability. In the event of breakage, this glass shatters into small pieces, providing safety. Due to its strength and safety features, tempered glass is used in many applications.

Features of Tempered Glass

- High Mechanical Strength: Tempered glass is approximately 4-5 times stronger than standard flat glass.

- Thermal Resistance: It is highly resistant to temperature changes, making it suitable for environments with sudden temperature fluctuations.

- Safety: When tempered glass breaks, it shatters into small, rounded pieces. These pieces are not sharp, minimizing the risk of injury.

- Flexibility: It has a greater capacity to flex under mechanical stress compared to standard glass.

You can download our latest catalog for detailed information about our machinery park and products.

Tempered Glass Production Process

The production of tempered glass consists of the following stages:

Cutting and Processing:

– Before starting the tempering process, the glass is cut to the desired size and shape.

– After cutting, edge treatments are applied to reduce the risk of cracking. Processes like cutting and drilling must be completed before tempering because these can cause the glass to break afterward.

Heating:

– The prepared glass is heated in a special tempering furnace to around 600-650°C.

– During this stage, the glass is heated to a temperature where it becomes soft enough to process.

Rapid Cooling (Tempering):

-The heated glass undergoes the tempering process, during which the surfaces cool rapidly while the interior cools more slowly.

-This rapid cooling process creates high compressive stresses on the surface and tensile stresses in the interior, which is the key feature that enhances the durability of tempered glass.

Architecture and Construction

- Building Glass

- Glass doors and windows

- Shower cabins

- Balcony and staircase railings

Automotive Industry

- Side and rear windows (for safety and durability purposes)

Furniture and Decoration

- Glass tables

- Showcase and shelving systems

Electronics and Home Appliances

- Oven doors

- Microwave and stove surfaces

Security and Protection

- Explosion and impact-resistant glass

Advantages of Tempered Glass

- High durability

- Safe breakage structure

- Resistance to heat and mechanical stress

- Long-lasting use

Tempered glass is an ideal solution for applications that require both safety and durability. As one of the most important products of modern glass technology, tempered glass enhances safety in many areas of daily life while offering an aesthetic appearance.

Trakya Glass and Aluminum Industry & Trade Inc.

Now in Silivri with Next-Generation Production Facilities! As of August 2024, we have relocated from our Selimpaşa factory to Silivri, taking a significant step to increase our production capacity and operate in a state-of-the-art manufacturing facility equipped with modern technologies. Continued…